Wear Resistance Alumina Ceramic Mosaic Square Lining for Chutes

Basic Info.

| Model NO. | tile |

| Wear Rate ‰ | <0.1 |

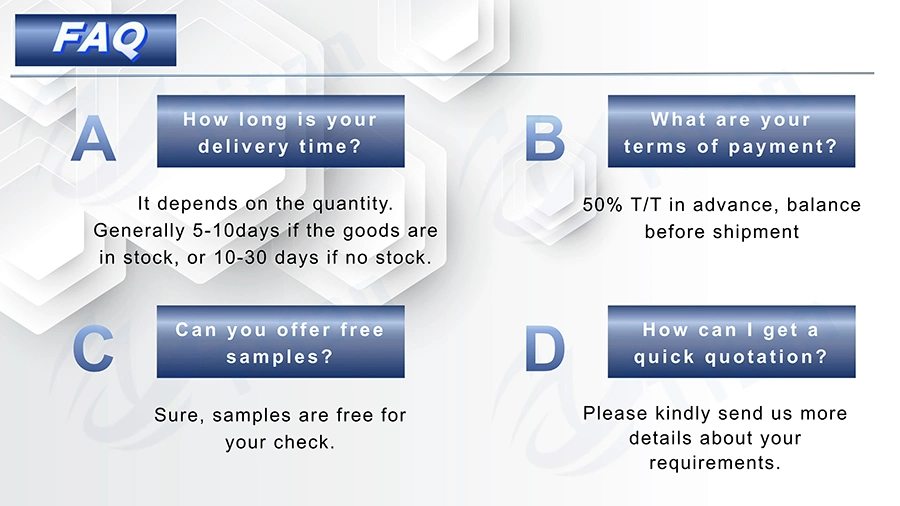

| Sample Time | 5-8 Days |

| Shape | Square, Circle, Hexagon |

| Bulk Order Time | 15-30 Days |

| Size | Customzied |

| Transport Package | by Cartons and Pallet |

| Specification | Thickness 3-10mm |

| Trademark | TITAN INDUSTRIAL CERAMIC |

| Origin | Shandong, China |

| HS Code | 690912 |

| Production Capacity | 17000 Tons Per Year |

Packaging & Delivery

Package Size 32.00cm * 18.50cm * 11.00cm Package Gross Weight 25.000kgProduct Description

Product Details

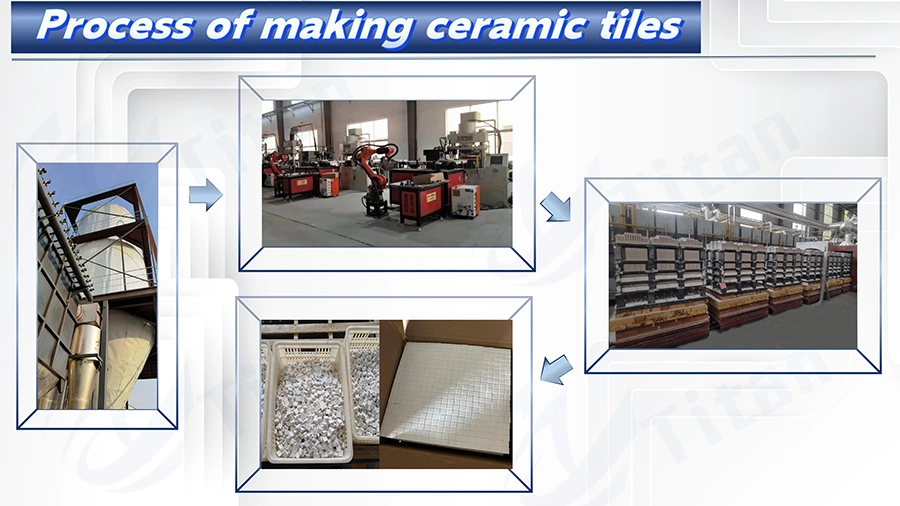

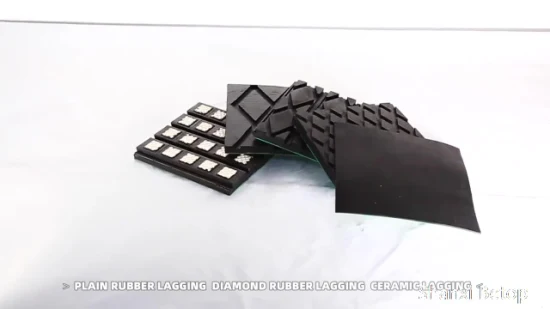

Ceramic Tile is a special corundum ceramic made of Al2O3 as the main raw material and rare metal oxide as the solvent, which is calcined at a high temperature of 1700 ºC.

Impact resistant and wear-resistant ceramic sheet is a new type of wear-resistant material, which greatly improves the impact resistance of ceramics by combining rubber and ceramics. It is very suitable for the use of wear-resistant protection in the position with large frontal impact.We adopt the mode of direct selling by manufacturers, remove the intermediate link, and greatly reduce the cost, so our price is very competitive in the industry.

Product Advantages

1. High hardness, its Rockwell hardness is HRA80-90, the hardness is second only to diamond2. Long service life, under the same working conditions, the service life of the equipment can be extended by more than 10 times.3. Light weight, its density is 3.6g/cm3, which can greatly reduce equipment load.4. The bonding is firm and the heat resistance is good. The hexagonal ceramic tile mat is pasted on the inner wall of the equipment with heat-resistant super glue.

Application

Widely used in anti-wear material conveying systems in coal, thermal power, steel, cement, mining, port, chemical and other industries, such as coal washing plants, thermal power plants, coal pipes, coal hoppers; coke hoppers in steel plants; mining transfer hoppers; cement plant clinker, cement chute, hopper.

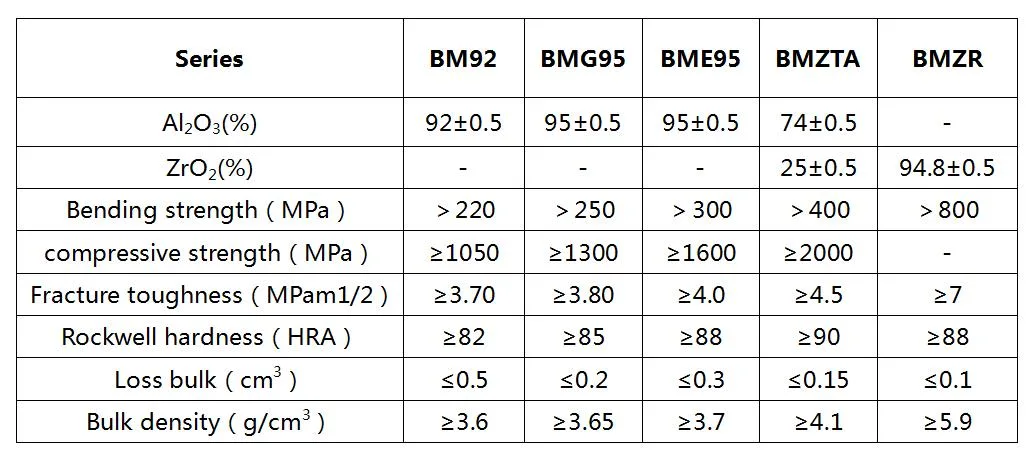

Technical Data