Conveyor Roller Drum Diamond Ceramic Rubber Pulley Lagging Lining Coating Sheet Price

Conveyor drum diamond ceramic rubber pulley lagging sheet price About Us:1. Factory specialized in rubber pulley lagging

Basic Info.

| Model NO. | DB-LZ |

| Color | Green Cn Layer, Black Rubber, White Ceramic |

| Transport Package | Plywood Case |

| Specification | 15mm x 500mm |

| Trademark | JZDB |

| Origin | Jiaozuo, Henan, China |

| Production Capacity | 500 PCS/Week |

Product Description

Conveyor drum diamond ceramic rubber pulley lagging sheet priceAbout Us:1. Factory specialized in rubber pulley lagging, ceramic drum lagging, wear resistant rubber sheet, etc2. Extensive experience in the production and application of pulley lagging3. Reliable factory, good delivery, resonable price4. Advanced production line and testing machine for rubber, polyurethane, ceramic products, etc5. ISO9001:2015, 14001:2015, 45001:2018Ceramic Rubber Lagging InspectionsFore More Information, just contact Demi LiAbout Conveyor Pulley LaggingThere will be normal or unexpected wear or aging issues after a long term operation, and such issues may cause accidents which will affect the normal operation of conveyor system.Pulley lagging can increase the coefficient friction, reduce wear to the pulley and belt, and offer proper grip to belt. Pulley lagging helps to extend service life of pulley and belt. It can also improve the operation and avoide belt slippage significantly.Types of Pulley Laggings We Produce:1. Ceramic pulley lagging2. Rubber pulley lagging sheet, Diamond pattern, Smooth surface, Herringbone pattern3. Polyurethane pulley lagging4. Replaceable Weld On pulley lagging5. Replaceable bolt on rubber pulley lagging6. Bolt on ceramic laggingDescription Ceramic Rubber LaggingCeramic rubber lagging sheets comprise of high alumina tiles, rubber matrix and a cn bonding layer, which ensures fast and high bonding strength.The high alumina tiles deliver excellent wear resistance and help increase service life of lagging significantly, commonly its wear life is 8~10 times as long as rubber lagging.Ceramic lagging is specially suited for pulleys where slippage and excessive wear and tear problems make normal rubber lagging ineffective. The alumina ceramic tiles with diamond nibbles help in proper grip of the belt under wet, muddy or any other such arduous conditions. The grooves between two rows of ceramic tiles help to eliminate the muddy, dusts, water, etc.Available sizes of ceramic rubber laggingThickness: 12mm, 15mm, 20mm, 25mm, etcWidth: 500mmLength: 800mm, 1000mm, 1220mm, 1450mm, 1650mm, 1850mm, 2050mm, 2250mm, 2550mm, etcCeramic rubber lagging sheet can also be produced in rolls, below picture is 10 meter long ceramic rubber lagging

Technical Data Sheet Of ceramic Rubber Lagging

| Ceramic Tiles | |

| Al2O3 | 95% |

| Ceramic Hardness (Mohs) | >9t |

| Working Temperature | -40~85ºC |

| Rubber | |

| Material | NR, SBR, Blended Rubber |

| Hardness | 65+/-5 Shroe A |

| Density | 1.15+/-0.05 g/cm3 |

| Tensile Strength | 20 MPa |

| Elongation At Break | 550% |

| Wear Loss | <=100mm3 |

We also provide pulley lagging service, at mine site or pulley manufacturerRubber Pulley LaggingRubber pulley lagging can reduce belt slippage and extend service life of conveyor belt.Features of Rubber Lagging1. Reduce belt slippage2. Extend belt and pulley life3. Available in natural rubber and FRAS approved rubber4. With cn bonding layerThe size of our rubber lagging is 2 meter wide x 10 meter long, plain surface, diamond pattern or herringbone pattern. The diamond pattern is oriented to 10 meter side. You can get what you require by cutting, like 1200mm wide, 1400mm wide, 1600mm wide, 1800mm wide, etc. It's very effective for inventory reserving.Technical Data Sheet of Rubber Pulley Lagging:

| Material | NR, SBR |

| Tensile Strength | 20 MPa |

| Elongation at Break | 600% |

| Hardness | 63+/-5 Shore A |

| Abrasion Loss | 110mm3 |

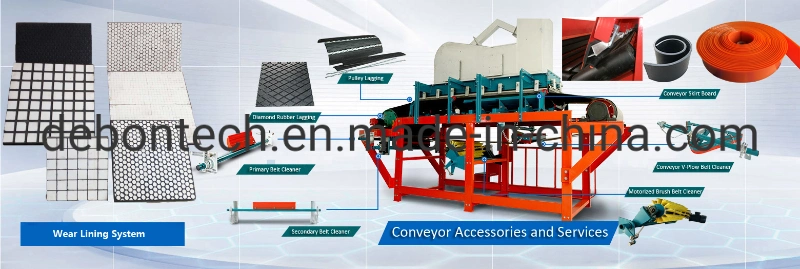

QA/QCThe raw material, semi-finished products and final products will all be tested.We have professional labs with all necessary equipment, such as Moving Die Rheometer, universal testing machine, roller grinding machine, megger, ageing oven, alcohol balst burner, ceramic analysis apparatuses, etcEach batch of raw materials will be inspected and tested. Repid tests are carried out for each batch of rubber compound to ensure rubber properties. We takes samples from finished pulley lagging sheets via the samples taking machine to test the tensile strength, elongation, aging, electrical resistance, wear loss, etc.The Mettler Toledo Ingredient Scale is used to make sure that the ingredients are accurate.Zero defect managment to inspire the workers to pay much attention to quality and avoid defectives. The Quality Awards are settled to award the workers, and for those who have zero defective product, their salaries will be increased by 20%Three inspection system is used to ensure the quality: self-inspection, mutual-inspection and special-inspection-The first-piece inspection and enough in-process inspections will be done by the operators. Defective products should be treated and placed separately.The workers are required to fill in and sign the inspection record cards.-Sampling the semi-products from last procedureMutual-inspection must be done where the workers change shifts. The engineers and group leaders will do sampling inspection during the production-Professional QC staffs are employed to inspect the complete production of pulley lagging sheets, from rubber comound to vulcanization. Detailed records are filed so that the products can be traced.-We have over 20 pulley lagging installation staffs who have been trained rigorously and have extensive experience. All pulley lagging services shall strictly follow the installation instructions and will be recorded.Cold-bond pulley lagging installation instructions are available as per requests.About FactoryJiaozuo Debon Technology Co., Ltd, its former name is Jiaozuo Zhuoer Machinery Manufacturer Co., Ltd, is founded in 2001, is a factory dedicated to the research and developement, manufacturing and application for wear products in mining and other industries and conveyor accessories in material handling industry.Our factory has advanced production line and testing machine for rubber, polyurethane, ceramic products,etc..The main products: pulley lagging, belt cleaner, conveyor skirt board, ceramic liner and ceramic rubber liner, wear resistant rubber sheet, polyurethane sheet, etcOur products are widely in conveyor system and wear solutions for mining equipments. We exported to many countries and areas including Australia, Canada, Russia, Europe, Chile, America, Southeast Asia, etc. We also have good reputation and market share in domestic market. Our customers prove the high quality and consistency.

Send to us